wearing ring in centrifugal pump|impeller clearance chart : wholesale Installing wear rings is an economical and efficient way to restore a pump’s performance as well as protect against excessive casing temperature, cavitation, vibration, and noise. In our next post, we will review the energy . WEB31 de mai. de 2022 · Dal Piemonte alla Calabria in cinque mesi: Creditime apre una nuova sede a Lamezia Terme. 1.247 chilometri separano Torino da Lamezia Terme. In appena cinque mesi abbiamo coperto questa distanza e portato Creditime anche in Calabria dove, a breve, apriremo una nuova sede. In questo periodo abbiamo lavorato intensamente, .

{plog:ftitle_list}

webcÓdigos lucrativos oficial Eu sei que você já está cansado de ver falsas promessas na internet e está com medo do CÓDIGOS LUCRATIVOS ser apenas mais uma dessas promessas. Mas nós confiamos tanto no nosso trabalho, que estamos te dando uma garantia incondicional de 30 dias.

What is the use of Wear rings in centrifugal pumps? Wear rings, also known as wearing rings or impeller wear rings, are important components used in centrifugal pumps to reduce fluid leakage and improve pump performance. . Wear rings play a crucial role in centrifugal pumps. A centrifugal pump typically features two adjacent wear rings: a stationary wear ring on the casing and a rotating wear . A wear ring, also known as a wear plate or wear ring insert, is a critical component in centrifugal pumps. It is a replaceable part typically made from materials such as bronze, cast iron, or stainless steel.Wearing rings are replaceable rings that are attached to the impeller and/or the pump casing to allow a small running clearance between the impeller and the pump casing without causing wear of the actual impeller or pump casing .

Installing wear rings is an economical and efficient way to restore a pump’s performance as well as protect against excessive casing temperature, cavitation, vibration, and noise. In our next post, we will review the energy .

Centrifugal pump wear rings are vital components that enhance the efficiency and longevity of pumps by minimizing leakage and protecting critical parts from wear. Regular maintenance, including measuring and adjusting wear ring . One of a wear rings’ primary functions is to provide a restrictive annulus between different pressure regimes within a centrifugal pump. Because of this function, one side of the wear ring operates at higher pressure than the .

Reducing the wear ring clearance in a centrifugal pump is a significant reliability upgrade because it increases rotor damping and stiffness in the pump. In more practical terms, reducing wear ring clearance decreases .An Older plant can use the power of the wear rings to increase the shaft stiffness for hundreds of pumps. The stability generated by the wear rings is generally referred to as the Lomakin .

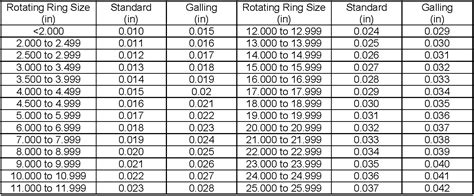

impeller wear ring clearance table

Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. To restore efficient, reliable operation and prevent catastrophic pump failure, it is critical . Because the clearance cannot be reduced between two metal rings without an increased risk of pump seizure, metal wear rings limit pump efficiency. Using non-metallic wear rings, the metal-to-metal interfaces within . Effects Of Increase In Wear Ring Clearance On Centrifugal Pumps. A wear ring affects the working and performance of an centrifugal pump in a significant way. Centrifugal pumps with high wear ring clearance .

Section 2: How to Measure Wear Ring Clearance in Centrifugal Pumps Measuring wear ring clearance involves using precise instruments to determine the gap between the casing and impeller wear rings. Regular measurements help identify when adjustments or replacements are needed to maintain optimal pump performance.

As operating plants age, so does their equipment. Pumps will need to be replaced or repaired, and in many cases, upgraded. A non-metallic wear ring is an option that may make the pump more reliable and increase its efficiency and safety. Conclusion. Good pump wear rings for your centrifugal pumps will improve both performance and efficiency.

One of the most common repairs on centrifugal pumps is replacing worn or damaged wear . Pumps & Systems June 2019: Wear Ring Clearance For Centrifugal Pumps Understand the pump specific speed to help establish proper tolerance.Both impeller and case wear rings are commonly found in centrifugal pumps. These pumps are used in many applications to transfer energy by centrifugal force. As the impeller of the centrifugal pump rotates, the fluid is pushed outward along the circumference and directs the flow towards the pump outlet as depicted in Figure 1 . These blades are fixed to the diffuser ring. The space between the blades defines the direction of the liquid flow. Fluid from the impeller flows through the cavities under high pressure. Upon exiting the blade, the liquid enters the housing of a volute or spherical shape. . Centrifugal pump has less wear and tear and can handle dirty water. As centrifugal pumps must transport liquids by imparting kinetic energy to the fluid, the impeller of a centrifugal pump must rotate at a fast velocity to do this. Due to shaft deflection, these high speeds may cause excessive wear on the impeller and casing, leading to premature failure. How Wear Rings Help to Improve Pump Performance. With .

It is also worth considering the effect of wear ring clearances on pump vibration. With a reduction in clearance, the effective shaft stiffness will increase. . Reference: API Standard for Centrifugal Pumps, 11 th Edition. Most popular related searches. centrifugal pump; centrifugal pumping; impeller pump; wear metal; reference standard .Wearing Rings. Centrifugal pumps contain rotating impellers within stationary pump casings. To allow the impeller to rotate freely within the pump casing, a small clearance is designed to be maintained between the impeller and the pump casing. To maximize the efficiency of a centrifugal pump, it is necessary to minimize the amount of liquid .h. Lantern Ring i. Impeller wearing ring j. Pump casing wearing ring. Introduction. Centrifugal pumps basically consist of a stationary pump casing and an impeller mounted on a rotating shaft. The pump casing provides a pressure boundary for the pump and contains channels to properly direct the suction and discharge flow. The pump casing has .The centrifugal pump is a type of pump that uses the kinetic energy of a rotating impeller to impart motion to the luid, see igure 1.1. The rotating impeller acceler- . Closed pump impellers with wear rings can have near balanced (zero) axial load or more usually low axial load directed towards the suction. With in-

Centrifugal Pumps atau Pompa Sentrifugal ini memiliki elemen utama yaitu motor penggerak dengan sudu Impeller yang berputar dengan kecepatan tinggi. . Wearing ring casing merupakan bagian dari pompa sentrifugal atau centrifugal pumps yang dipasang pada casing agar tidak terjadi kebocoran yang disebabkan oleh adanya celah pada casing dan . Wear rings are also susceptible to erosion cor rosion and should be . Erosion wear of the centrifugal pump components is considered one of the principal hurdles for pumping and transporting the .h. Lantern Ring i. Impeller wearing ring j. Pump casing wearing ring Introduction Centrifugal pumps basically consist of a stationary pump casing and an impeller mounted on a rotating shaft. The pump casing provides a pressure boundary for the pump and contains channels to properly direct the suction and discharge flow. The pump casing has . Learn about nine different centrifugal pump parts that you may find in almost all pumps.Body, Casing, Impeller, Wear Ring, Shaft, coupling, Bearing and Beari.

Gene Vogel EASA Pump & Vibration Specialist One of the most common repairs on centrifugal pumps is replacing worn or damaged wear rings. For pumps with closed style impellers (impellers with a front shroud as described below), there will be a casing wear ring and possibly an impeller wear ring which is fitted to the outside diameter (OD) of the impeller suction eye. .

Why wearing ring change in centrifugal pump? To improve the performance of the centrifugal pump and reduce noise and vibration within the pump, when the clearance between both wear rings exceeds .

In centrifugal pumps, wear materials are used as a buffer between rotating and stationary parts. Historically, these components have been metallic in nature. To avoid galling and possible equipment seizure, dynamic metal clearances . casing and impeller for the composite wear ring and pump hardware (casing ID and impeller shaft OD). This content was downloaded from IP address 94.176.119.229 on 24/11/2022 at 05:56 Install and Replace Wear Rings. April 17, 2020 . The video we are featuring today, shows how to easily and efficiently install and replace wear rings on a centrifugal pump backplate. Watch this procedure, and learn more about pump repair and maintenance on our YouTube Channel. You can also suggest new video topics at [email protected].

Both case wear rings and impeller are commonly found in centrifugal pumps. These pumps transfer energy by centrifugal force and are used in many applications . The centrifugal pump’s impeller rotates, pushing the fluid outward along the circumference and directs the flow towards the pump outlet as depicted in Figure 1.The function of the impeller is to convert torque applied to the pump shaft to pressure and kinetic energy in the pumped liquid. It does this by the action of its vanes on the liquid and is the only component of a centrifugal pump that does so. The other components,.

wear ring stl tube 1026 pump 57 case 4.00 110.000.300: wear ring ss304 pump 63 case 0.00 110.000.301: wear ring brnz 932 pump 63 case .00 137.000.434: wear ring brnz 932 pump 103 case .00 137.000.565: wear ring brnz 932 pump 59 case 6.00 137.001.434: wear ring brnz 932 pump 97 case For years, the pump industry has had problems with centrifugal pumps. The continual wear of rings and bushings has been an issue. Despite many efforts to improve life and quality of these products, none have measured up to expectations. Now new wear rings and bushings can be molded and machined from proprietary bulk molding compounds produced . There is a difference in the effect of the pump curves between the wear of just the rings versus just the impeller (or a clogged impeller as you noted alternatively). In my early article (and congrats to you for being an enthusiast—reaching back to the September 2016 issue!), I focused on the rings issue, not the impeller per se.

tear strip test

tear test astm

WEBOur elected officials need to step up and protect us, future generations, our environment, and our health, by regulating the radiation emissions from wireless technologies being deployed at breakneck speed and holding the Communications Technology industry accountable for its direct and significant contribution to damages to our health and the .

wearing ring in centrifugal pump|impeller clearance chart